Mechanical Behavior of Materials at High Temperatures

Currently, we are running several programs on studying creep, creep-fatigue, thermo-mechanical fatigue and fracture behaviour of materials at high temperatures.

We are studying materials used in thermal coatings (e.g., bond coats, thermal barrier coating, etc.), boiler tubes and turbines in power plants (including advanced ultra-supercritical power plants), etc.

Here, we are particularly interested in developing testing methodologies suitable for evaluating small volume samples.

Besides standard small length scale mechanical testing, we are currently developing experimental and numerical techniques for evaluating creep behaviour of materials by testing cantilevers under bending and through nano-indentation.

We are collaborating with Professor Vikram Jayaram in these projects.

Devi Lal,

Syed Ali,

Ananya Tripathi,

Priya Goel

Faizan Hijazi

Sachin Kumar and

Raj Jung Mahat and

Aditya Kumar

are leading this effort.

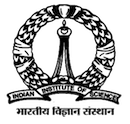

A few graphs showing the workings of bending creep: Top-left figure shows the distribution of stress across the thickness in steady state for different values of stress exponent (n). Top-right figure shows the loading scheme employed by us and the non-uniform stress distribution in cantilever during bending. Bottom- left image shows calculation of activation energy by plotting the log of steady state deflection rate as function of inverse of temperature. Bottom-right graph shows the variation of normalised strain rate as function of normalised stress that can be used to determine the value of stress exponent.

We are also investigating high temperature plasticity in pure single crystals, in particular 10 ppm purity [100]-oriented LiF single crystals and 99.999 % purity [100] and [111]-oriented Al single crystals.

In this series, we are also pondering over the open question of: What is the minimum dislocation density that can be attained purely by thermal treatment (i.e., annealing) –

does dislocation density continue to decrease or does it attain a universal minima?”

If so, then what is the fate of Harper-Dorn creep as an independent creep mechanism?

We are collaborating with Professor Michael Kassner of University of Southern California in these projects.

Shobhit Pratap Singh is leading this effort.

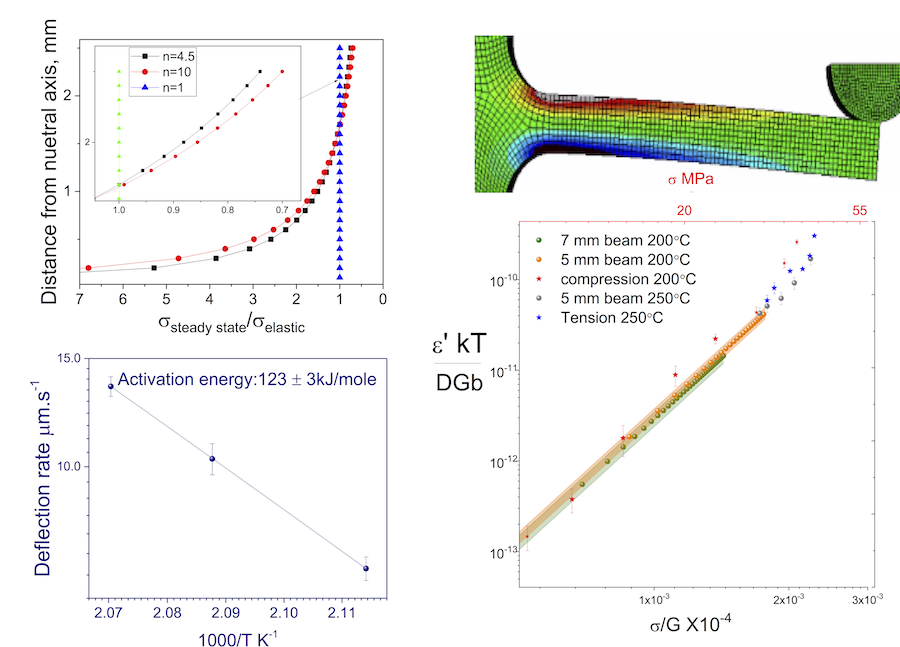

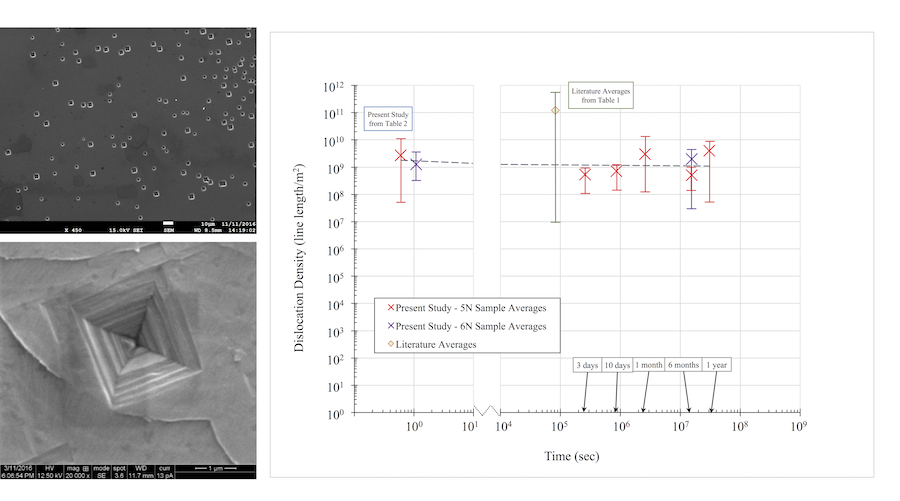

Top-left figure shows dislocation etch-pits in Al single crystal. Counting these etch-pits can give dislocation density. Bottom-left micrograph shows a close-up view of a dislocation etch-pit in LiF. Right graph shows the variation of dislocation density in (111)-oriented Al single crystal as function of annealing time.

Finally, we are also studying the effect of length scale of solder joints and electric current on the microstructural evolution and creep of Pb-free Sn-Ag-Cu solders.

Herein, we are particularly exploring the nature of microstructural evolution of solder joints during creep and the nature of the steady state creep.

Anwesha Kanjilal is leading this effort.

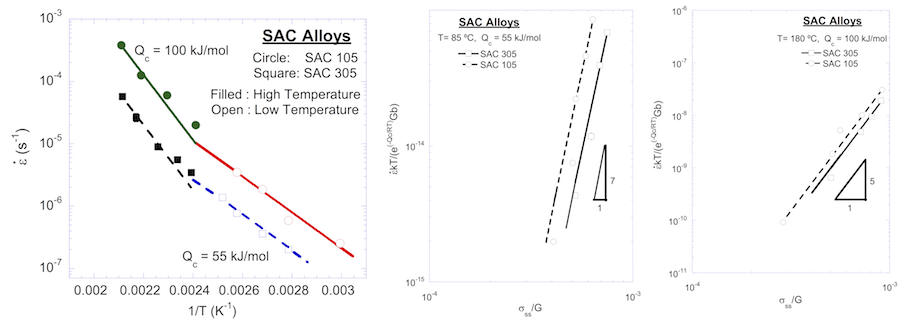

Left figure shows variation of the steady state strain rate as function of inverse of the temperature on a semi-log plot for two SAC alloys. The slope of such a plot can be used to calculate activation energy in different temperature ranges. Middle and right figures show variation of the normalised steady state strain rate as function of the normalised stress on log-log scale for two SAC alloys at two different temperatures. The slope of such a graph gives stress exponent.

Effect of Electro-Mechanical Coupling on Failure

We are interested in studying the effect of electro-magneto-mechanical coupling on the failure of pre-cracked metallic foils, sheets and plates.

We have observed that significant current crowding near crack tip along with the generated electro-magnetic (i.e., Lorentz) force can lead to partial

as well as complete failure of the structure. We are currently extending our work to also evaluate the effect of external magnetic field and microstructure

of such failure and if we can use the same for constructive purposes (e.g., machining).

Shubham Jain and

Swanand Telpande are currently leading this effort. Previously, Deepak Sharma led this study.

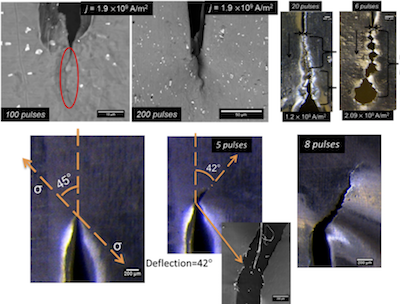

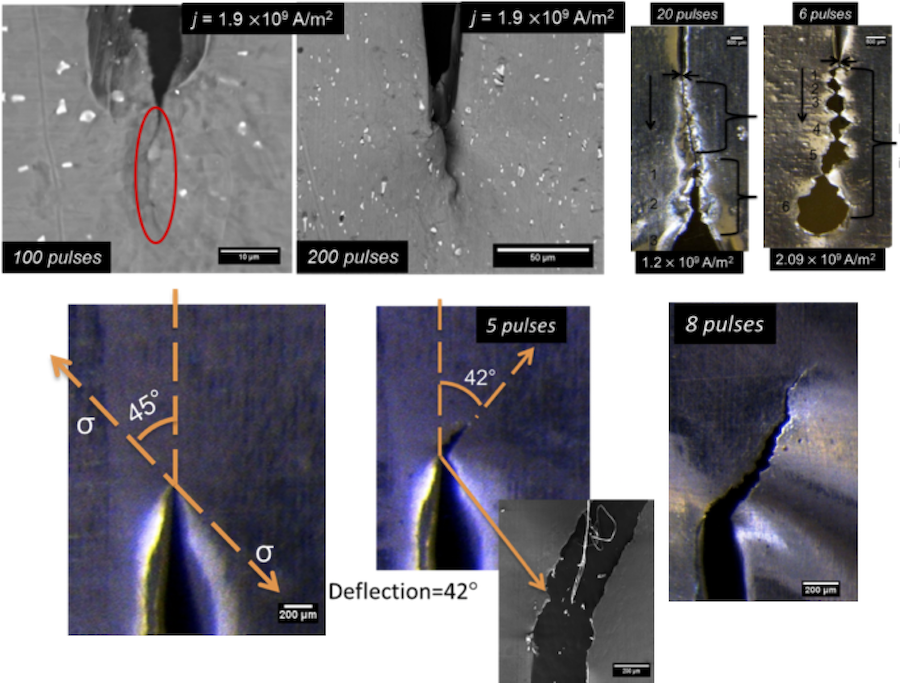

Figures in the top panel show effect of electric current pulses on growth of the crack: Left two micrographs show sharp crack propagation upon application of only electric current pulses, whereas the right two micrographs show formation and growth of blow hole as the crack grows longer or pulses of high current density is passed. Figures in the bottom pannel shows effect of application of a mechanical stress at an angle to the crack length as current pulses are passed.

Effects of Thermal Stress on Integrity of Metal-Si systems

We are studying effect of thermal cycling induced cyclic thermal stress on the structural integrity of metal-Si systems at various length scales.

We are particularly studying Cu filled through silicon via, solar cells, very thin films of Cu deposited on SiO2/Si substrate, etc.

Besides experiments, we are also developing FEM, crystal plasticity and, in collaboration with

Professor Abhik Choudhury , phase field modelling based understanding for related phenomenon in metal-Si systems.

Dipali Sonawane is working on this problem. Previously, Nalla Somaiah also focused on some aspect of this study.

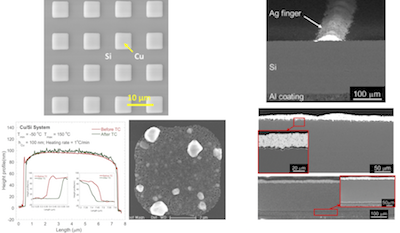

Figures in the left panel show effect of thermal cycling on Cu-Si thin film system: Top image shows the sample comprising Cu islands deposited on Si substrate, the bottom-left figure shows the profile of a Cu island before and after 3 thermal cycling and the bottom-right figure shows the top view of Cu island (revealing formation of hillocks) after 20 thermal cycles. Figures in the right panel show effect of thermal cycling on a commercial solar cell: Top image shows the sample before the test, middle figure shows the Ag-Si interface and bottom figures shows the Al-Si interface. Both Ag-Si and Al-Si interfaces registered delamination.

Effects of Severe Plastic Deformation on Mechanical and Electrical Behaviour

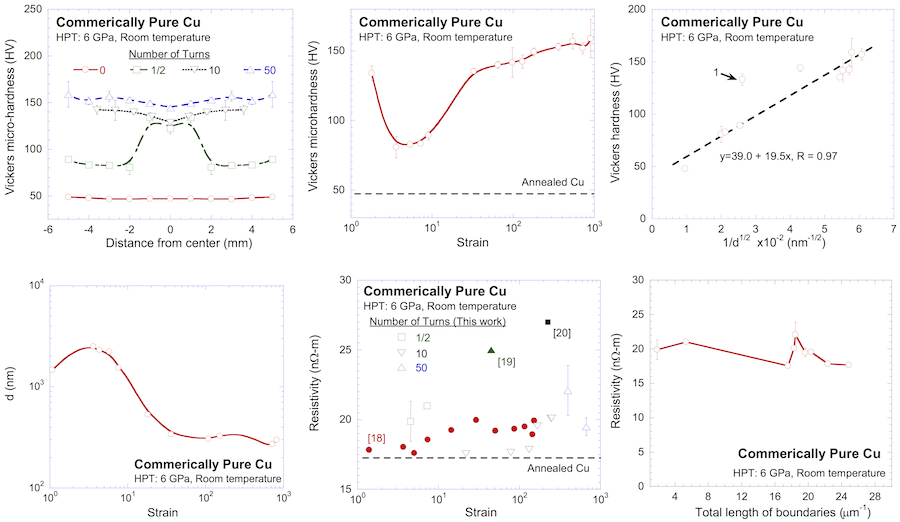

Severe plastic deformation has been one of our research interests and we continued working on some aspects of it intermittently. Currently, we are studying effect of high-pressure torsion on electrical conductivity and mechanical behaviour, including hardness and high cycle fatigue, of commercially pure Cu. We are also examining the effects of ambient ageing on strength-conductivity response of metals. We are collaborating with Professor Megumi Kawasaki of Oregon State University in this study.

Ajay Rijal is leading our effort on this problem. Previously, Shobhit Pratap Singh and Tarang Mungole also focused on some aspect of this study.

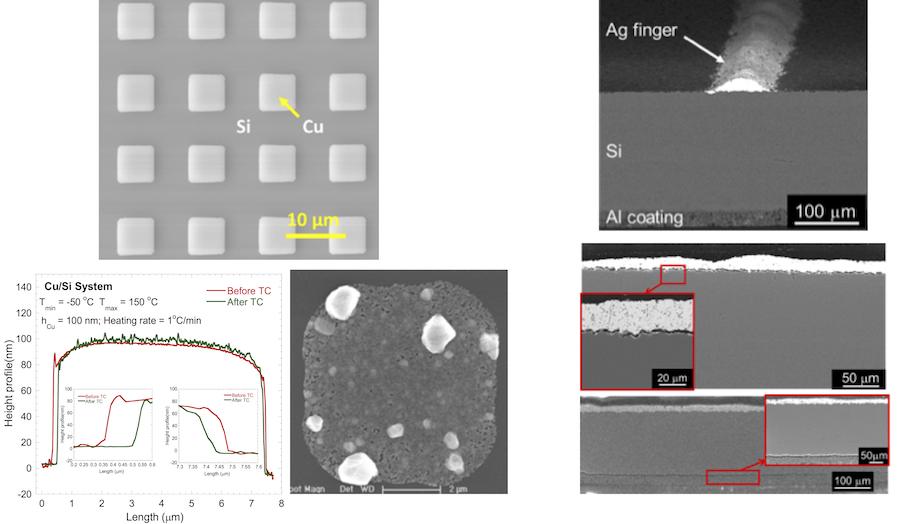

Figures showing evolution of different parameters with HPT processing: While the hardness varies as per Hall-Petch relationship (top-right graph), the resistivity of the sample did not show a monotonous variation with the total length of the boundaries (bottom-right graph).

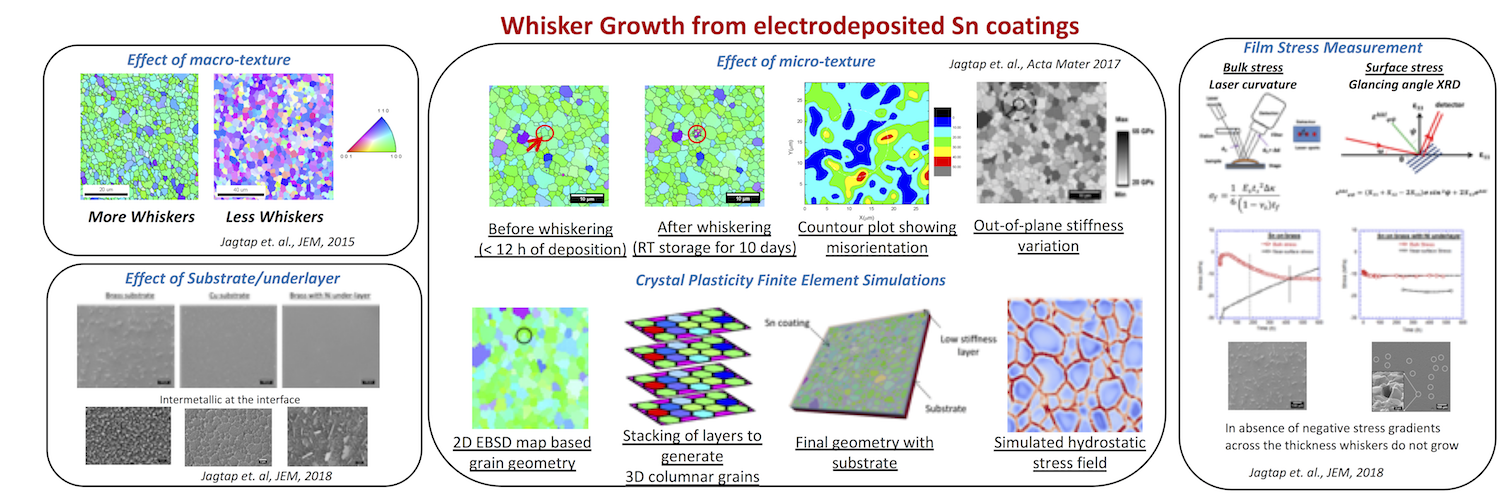

Mechanics and Materials Aspects of Tin Whiskering

Growth of filament type whiskers in metal films, especially Sn coating, is quite interesting to us.

Although it does not fit into classical definition of mechanical behaviour of materials, it has basic components that would be familiar to creep community!

By tracking the stress state and crystallographic texture of Sn coatings, we have been trying to pin-point the locations in Sn coating most prone to whiskering.

Currently, we are also studying effects of electric current on whiskering in Sn coatings.

Abhilash Agnihotri is leading this work. Previously,

Piyush Jagtap led this study.

Previous works on mechanical behavior of materials

<< Research Focus Electromigration >>