Electric Current Induced Flow of Very Thin Liquid Film

Often electromigration is considered as a reliability issue; however, we can apply this directional mass transport phenomenon to create useful patterns.

We discovered that application of electric current using a pointy electrode on thin film of Cr deposited on SiO2/Si substrate leads to melting and radially

symmetric flow of material from the cathode. Besides studying the fundamentals of the flow behaviour, we are also exploring possible applications of this

phenomenon, such as lithography, surface pattern formation, etc. It should be noted that such a flow does not require a metallic substrate or "rail"!

We are collaborating with Professor Rudra Pratap on this study.

Sumit Kumar is leading our effort in this direction. Prior to him Santanu Talukder led our work.

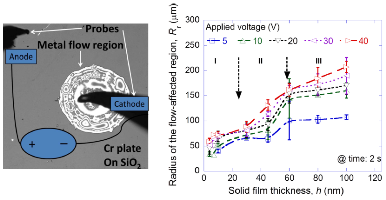

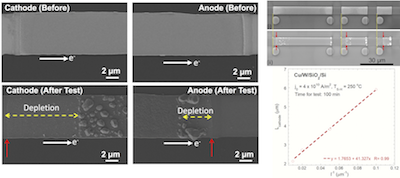

Picture on the left side shows the experimental set-up and the flow pattern formed upon application of an electric current. Picture on the right shows the effect of film thickness on the kinetics of the electric field induced flow. Click here for some interesting videos related to this phenomenon.

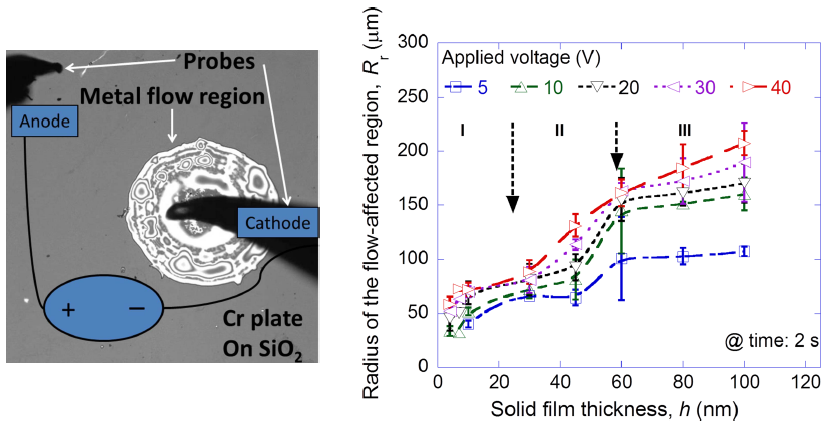

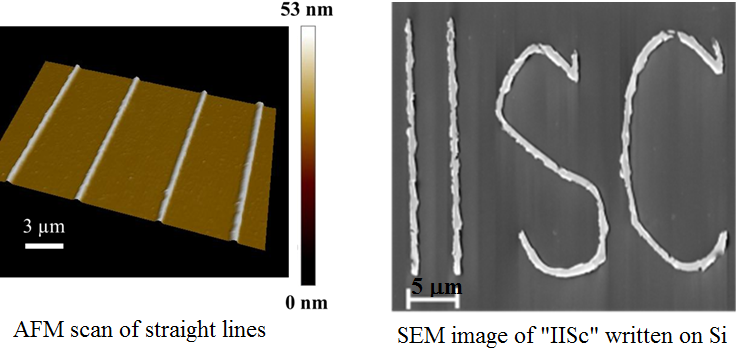

We have exploited the above phenomenon to develop a new lithography technique - which we call as electrolithography. Here, we use a thin metal film as a masking layer and a polymer layer beneath it as a pattern transfer layer. The desired pattern is drawn in the metal layer by etching the metal with a conducting scanning probe. The pattern drawn on the metal layer is transferred to the polymer layer by etching the polymer with an appropriate solvent. Subsequently, the pattern is transferred to the desired material layer using a film deposition technique followed by conventional lift-off process. Using this simple technique, we have achieved pattern resolutions of 9 nm on the polymer and 40 nm on transferring the pattern to another material.

A few example patterns drawn using electro-lithography.

Relevant References

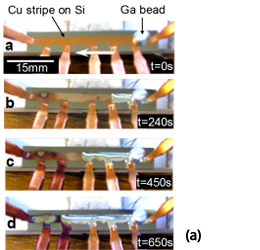

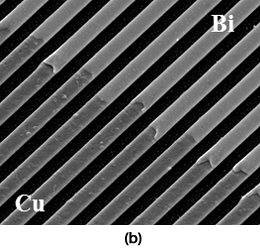

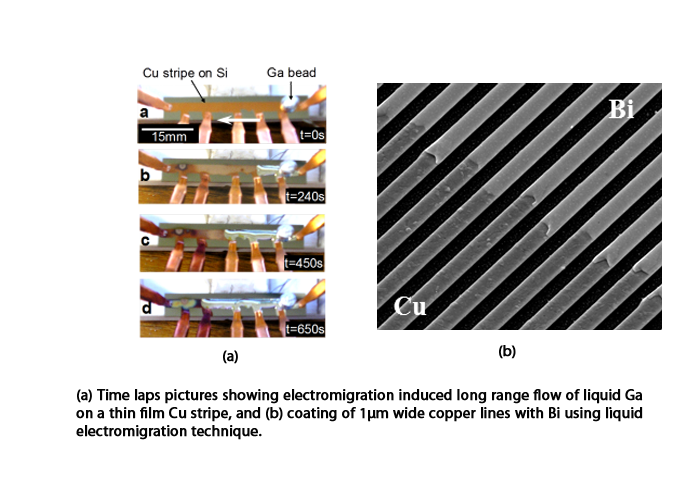

Electric Current Induced Long Range Flow of Liquid Metals

We discovered that continuous long range flow of liquid metals is possible with application

of an electric current through it. A small bead of a metal, such as Ga, In, Sn, Bi, Pb and Al was kept on a Cu thin film stripe,

and electric currents of large densities were passed. Due to Joule heating, the metal bead melted, and then the liquefied metal

flowed over large distances along the direction of the electric current. The liquid metal flow was exactly over the underlying

conductor path, irrespective of it being tortuous or straight. Kinetics measurement revealed that the electromigration assisted

flow of liquid metals was governed by self-diffusion. We observed that continuous long range flow of liquid metals on a conducting path is possible

if an electric current of high density is passed through it. The liquid metal flows exactly over the underlying conducting path, irrespective of it

being tortuous or straight. Kinetics measurement revealed that the electromigration assisted flow of liquid metals was governed by self-diffusion.

Now, we are exploring the effect of the substrate and the temperature on the solidified flow patterns.

Also, we are developing accurate physics and fluid-mechanics based analytical models for explaining the above phenomenon. In addition, we are exploring

ways to use this phenomenon for nano-soldering and precisely transporting minute amount of liquid metals.

We are collaborating with Professor Rudra Pratap on this study.

Vijayendra Shashtri is leading this work. In the past, Santanu Talukder and

Sumit Kumar also worked on some aspects of this project.

(a) Time laps pictures showing electromigration induced long range flow of liquid Ga on a thin film Cu stripe, and (b) coating of 1μm wide copper lines with Bi using liquid electromigration technique. Click here for some interesting videos.

Relevant ReferencesElectromigration-Thermomigration Coupling in Cu-Si Film Systems

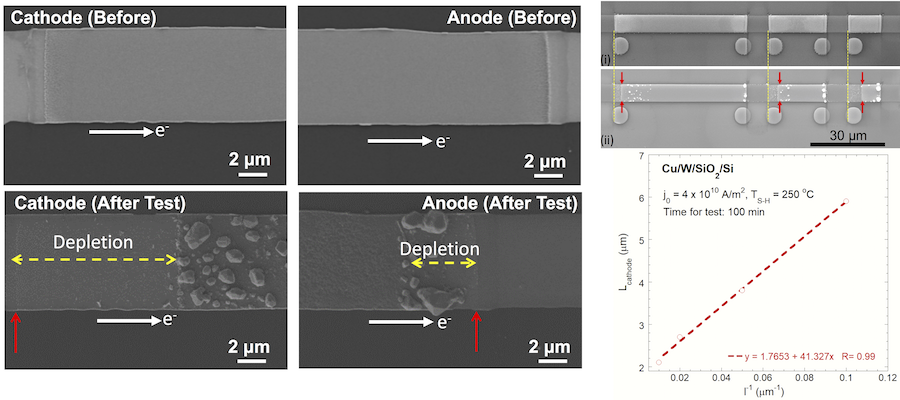

If an electric current of high density is passed through a thin film conductor having a bend or junction, then a temperature gradient is spontaneously generated

in the interconnects, especially near bends and junctions. In such a case, there can be significant coupling between electromigration and thermomigration that

can lead to anomalous mass transport in Cu films. A few such anomalous mass transport phenomena are inverse Blech length

(leading to an increase in the mass transport at the cathode with decrease in the sample length) and anomalous mass depletion at the anode upon

application of only electric current. Needless to say that these observations will have significant impact on the design of new generation thin film interconnects.

Beside analytically modelling of the electromigration-thermomigration coupling, we are also studying ways to minimize it via interfacial engineering.

Nalla Somaiah has been leading our effort in this direction.

The left panel of figures show the anode (left) and the cathode (right) before (top) and after (bottom) an electrical current loading. This set of figures shows the anomalous mass transport at the anode. The figures in the right panel show effect of sample length on the mass transport at the cathode - this reveals a linear increase in the depletion zone at the cathode with the inverse of the sample length.

Relevant References<< Mechanical Behavior Research Focus >>