Facilities Available

Users interested in booking the slots please submit the dully filled central facility usage form (below) in person to respective facility in-charge (or) book by online using the links provided under respective facility sections below:

Characterization Facilities

Optical Microscopy and Metallography laboratory

In-charge: Prof. S. Dasgupta, Prof. R. Ranjan, Prof. S. Bose

Optical Microscopes

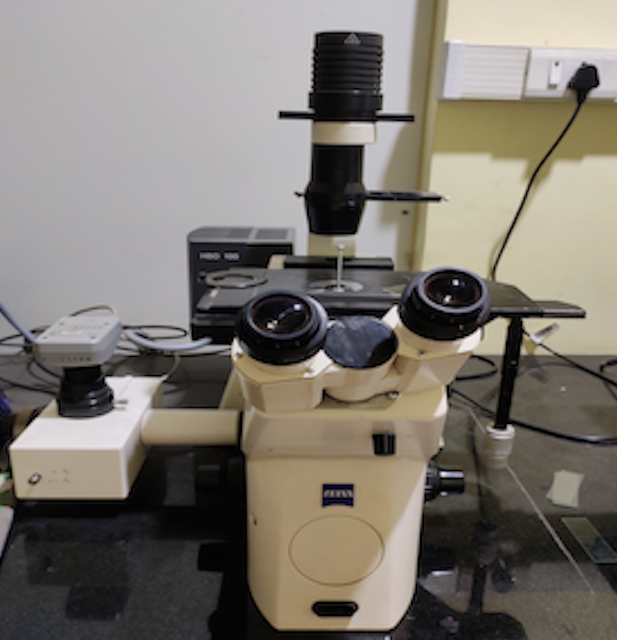

| Carl Zeiss (Inverted) | ||

|---|---|---|

|

||

| Model | MAT 200 Motorised Axio Vision (Version 4.7.2) | |

| Mode of Operation | BF/DF/TIC/Transmission/DIC slides | |

| Filters | Blue/Green/Yellow | |

| CCD | TWAINE CAMERA IMAGE ACQUISITION | |

| Halogen Bulb | HAL100: 12V, 100W and Bio-imaging using Fluorescence (HBO) attachments with 63x oil immersion objective | |

| Charges | Department ( per hour) | 200 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 1000 | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

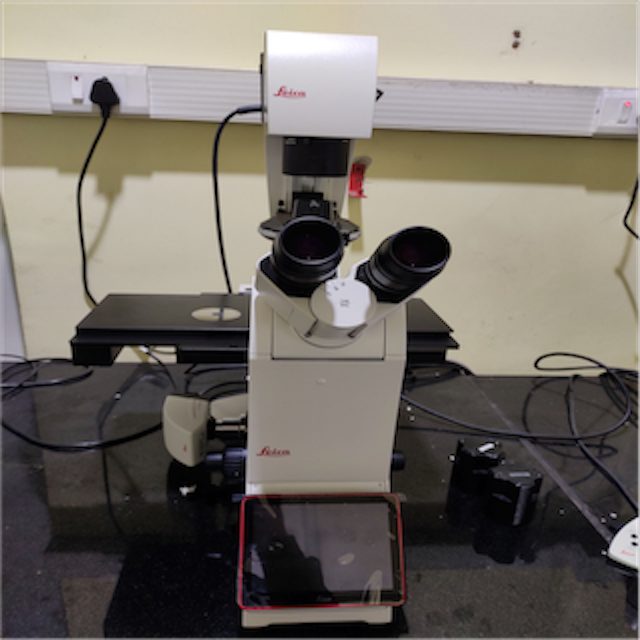

| Leica DMi8 | ||

|---|---|---|

|

||

| Model | DMi8 | |

| Mode of Operation | BF/DF/Phase contrast/DIC/Fluorescence contrast | |

| Charges | Department ( per hour) | 200 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 1000 | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

| Metallography | ||

|---|---|---|

| Struers dual disc polisher | ||

|

||

| Metco single and dual disc polisher | ||

|

||

| Diamond wheel cutter, Hot compaction and Abrasive Grinder | ||

|

||

| Automatic Polisher and Abrasive wheel cutting machine | ||

|

||

| Ultrasonic cleaning, etchants and Fume hood | ||

|

||

| Charges (one-time usage) | Department ( per hour) | 200 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 1000 | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

Electron Microscopy laboratory

In-charge: Dr. R. Ravi, Professor Subodh Kumar, Professor S. Dasgupta, Professor Satyam Suwas

| Scanning electron microscope (SEM) | ||

|---|---|---|

|

||

| Model | ESEM Quanta 200, FEI | |

| Source | W-Filament | |

| Detectors | E-T SE, Solid state BSE Energy Dispersive X-Ray Spectrometer (EDAX) |

|

| Charges (Rupees per hour) | Department ( per hour) | 500 |

| Academic ( per hour) | 1000 | |

| Industry ( per 3 hours) | 5000 + GST | |

| Contact person | Dr. Ravi R (emlab.mte@iisc.ac.in) Click this link for online booking | |

| Electron probe micro analyzer (EPMA) | ||

|---|---|---|

|

||

| Model | JEOL JXA-8530F | |

| Source | Thermal Field Emission | |

| Detectors | 6 WDS detector (3 for heavy elements and 3 for light elements), Energy Dispersive X-Ray Spectrometer, Back-scattered electron (BSE) detector | |

| Charges (Rupees per hour) | Department ( per hour) | 500 |

| Academic ( per hour) | 2500 | |

| Industry ( per hour) | 5000 + GST | |

| Contact person | Dr. Ravi R (emlab.mte@iisc.ac.in) Click this link for online booking. | |

| Atomic force microscope (AFM) | ||

|---|---|---|

|

||

| Model | JPK Nanowizard R3 | |

| Imaging Modes | Phase contrast, Force Modulation, Spreading Resistance | |

| Scan Range | 70 μm | |

| Drive Resolution | Z: 0.21 nm and XY: 1 nm | |

| Auto Approach | 5 mm with maximum speed 0.1mm/s | |

| Cantilevers | CONTR/NCLR (FREQUENCY: 15-300 kHz) | |

| Charges (Rupees per hour) | Department ( per hour) | 200 |

| Academic ( per hour) | 400 | |

| Industry ( per 3 hours) | 2000 | |

| Contact person | Prof. Sachin R. Rondiya (rondiya@iisc.ac.in) | |

| Scanning tunneling microscope (STM) | ||

|---|---|---|

|

||

| Model | ||

| Scan Range | 1 μm | |

| Maximum Z range | 200 nm | |

| Drive Resolution | Z: 0.21 nm and XY: 1 nm | |

| Tip-Sample approach | Stick-slip piezo motor | |

| Sample Size | Maximum 10 mm diameter | |

| Charges (Rupees per hour) | Department ( per hour) | |

| Academic ( per hour) | ||

| Industry ( per 3 hours) | ||

| Contact person | Prof. Praveen C. Ramamurthy (praveen@iisc.ac.in) | |

X-ray Diffraction Laboratory

In-charge: Professor R. Ranjan, Professor Satyam Suwas, Dr. G. S. Avadhani

Click this link for online booking.

| X-pert PRO | ||||||||

|---|---|---|---|---|---|---|---|---|

|

||||||||

| Model | X-Pert PRO, PANalytical | |||||||

| Target | Cu | |||||||

| Other specifications | Secondary graphite monochromator flat plate horizontal sample holder, X-Celerator* for faster data acquisition, X-Pert Hi-Score plus software pattern analysis and phase identification (ICDD data base) |

|||||||

| Charges (Rupees per hour) | Department ( per hour) | 250 | ||||||

| Academic ( per hour) | 500 | |||||||

| Industry ( per 3 hours) | 2500 | |||||||

| Contact person | Dr. G.S. Avadhani (gsa@@iisc.ac.in) | |||||||

| Rigaku | ||

|---|---|---|

|

||

| Model | Rigaku Smart Lab | |

| Target | Cu | |

| Other specifications | ||

| Charges (Rupees per hour) | Department ( per hour) | 250 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 2500 | |

| Contact person | Dr. G.S. Avadhani (gsa@@iisc.ac.in) | |

| X-ray radiography | ||||||||

|---|---|---|---|---|---|---|---|---|

|

||||||||

| Model | Stenoscope 9000 | |||||||

| Description | Mobile medical X-ray unit equipped with a C-arm, on which an image intensifier and X-ray source are mounted. The X-ray system enables operation in one of several modes: standard radiography, high-resolution fluoroscopy, pulsed fluoroscopy, and standard fluoroscopy. Up to 50 min of continuous X-ray emission in the fluoroscopy mode allowed collection of the high-quality, distortion-free images |

|||||||

| Operating Modes | Standard radiography, high-resolution fluoroscopy, pulsed fluoroscopy, and standard fluoroscopy | |||||||

| Voltage and Current range | 40 to 110 kV 0.1 to 6 mA |

|||||||

| Charges (Rupees per hour) | Department ( per hour) | 200 | ||||||

| Academic ( per hour) | 500 | |||||||

| Industry ( per 3 hours) | 3000 | |||||||

| Contact person | Prof. Govind S. Gupta (govindg@iisc.ac.in) | |||||||

Residual Stress (Laser)

| Thin film residual stress measurement | ||

|---|---|---|

|

||

| Model | KLA Tencor FLX 2320 | |

| Description | Measures curvature of plates and beams using laser. Temperatures down to 0°C. Dual beam for stresses measurements for transparent coatings | |

| Heating Stage | Heating stage up to 500°C in ambient atmospheres or under inert gas | |

| Statical Strain | Maximum size is 8 inches wafer. Plates, disks, beams with longest measurable length less than 8 inches dia. can also be used | |

| Charges (Rupees per hour) | Department ( per hour) | |

| Academic ( per hour) | ||

| Industry ( per 3 hours) | ||

| Contact person | Prof. Praveen Kumar (praveenk@iisc.ac.in) | |

Thermal Characterization Laboratory

In-charge: Professor S. Kumar, Professor S. Karthikeyan, Dr. P. Padaikathan

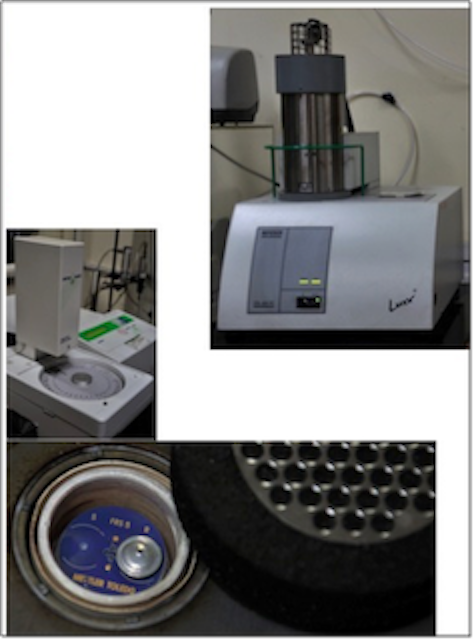

| Differential scanning calorimeter (DSC) | ||

|---|---|---|

|

||

| Model | Mettler-Toledo DSC 822e | |

| Specifications | Sample mass/volume: minimum of 0.5 -20mg/up to 150ul Temperature range: Between -150°C and +70°C Cooling option: Liquid Nitrogen (pressurized to 20-30psi) Heating rate: 2—50 K/min Cooling rate: from 500°C to 100°C in 8min |

|

| Resolution | 0.4 μW | |

| Other Features | Auto-Sampler Robot (for 32 No. of tests) and LN2 – Dewar capacity 240litre | |

| Charges (Rupees per hour) | Department ( per hour) | 250 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 2500 | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

|

||

| Model | NETZSCH STA 449 F-3 Jupiter | |

| Specifications | Sample mass/volume: up to 35 mg Temperature range: Between RT and 1500°C |

|

| Atmosphere | Vacuum/Argon | |

| Charges (Rupees per hour) | Department ( per hour) | 250 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 2500 | |

| Contact person | Prof. Surendra Kumar Makineni (skmakineni@iisc.ac.in) | |

| TG-DSC and TG-DTA | ||

|---|---|---|

|

||

| Model | NETZSCH STA 409 | |

| Specifications | Temperature range: 25°C to 1600°C (SiC: HEATING ELEMENT) Heating and cooling rates: 5 K/min to 50 K/min Weighing range: 200 mg |

|

| Resolution | TGA: up to 0.002 mg and DSC < 1 μW | |

| Atmosphere | inert, oxidizing, reducing, static, dynamic | |

| Other Features | TG features: Automatic evaluation of mass-change steps, Calculation of mass/temperature values and residual mass, Automatic baseline DSC/DTA features: Determination of onset, peak, inflection and end temperatures, Automatic peak search, Comprehensive analysis of glass transitions |

|

| Charges (Rupees per hour) | Department ( per hour) | 250 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 2500 | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

Particle and Pore Characterization Laboratory

In-charge: Professor A. M. Raichur, Professor P. C. Ramamurthy, Dr. P. Padaikathan, Mr. R. J. Deshpande

| Atomic absorption spectrometer | ||

|---|---|---|

|

||

| Model | Series AA Spectrometer, Thermo Electron Corporation | |

| Elements analysed | Common elements including base metals and alkaline earth metals | |

| Monochromator | HR 640 monochromator incorporating a holographic grating with 2400 grooves/mm with a linear dispersion of 0.6nm/mm | |

| Instrument Sensitivity | ~0.05ppm | |

| Range | Up to 5ppm | |

| Charges (Rupees per hour) | Department ( per hour) | 250 |

| Academic ( per hour) | 1000 | |

| Industry ( per 3 hours) | 3000 + GST | |

| Contact person | Mr. R.J. Deshpande (rjd@iisc.ac.in) | |

| Particle size analyzer | ||

|---|---|---|

|

||

| Model | Zetasizer Nanoseries-ZEN 3690 (Malvern Instruments) | |

| Particle size range | 1 nm to 3 µm | |

| Size range for zeta potential | 5 nm to 10 µm | |

| Charges (Rupees per hour) | Department ( per hour) | 250 |

| Academic ( per hour) | 1000 | |

| Industry ( per 3 hours) | 3000 + GST | |

| Contact person | Mr. R.J. Deshpande (rjd@iisc.ac.in) | |

| Automatic micropore physisorption analyzer | ||

|---|---|---|

|

||

| Model | Micromeritics ASAP 2020 | |

| Analysis Gases | N2, Ar, CO2, O2, Kr, CO, Butane or any non-corrosive gas | |

| Analytical Techniques | Single-point BET surface area, Multi-point BET surface area, Adsorption isotherm, Desorption isotherms, Langmuir surface area, BJH Mesopore volume, BJH Mesopore area, Total pore volume, deBoer t-Plot & others, MP-Method, Micropore Volume, Micropore Surface Area, Micropore Size Distribution, a s Plot, f-Ratio plot, Heat of adsorption, Freundlich & Temkin, Density Functional Theory, Reference isotherms, Horvath-Kawazoe, Dubinin-Radushkevich, Dubinin-Astakhov and Graph Overlays | |

| Operating Specifications | Surface Area Range 0.0005 m2/g and up Pore Diameter Range : 3.5 – 5000 Angstroms Micropore Volume: Detectable within 0.0001 cc/g |

|

| Pressure Measurement Resolution | 0 to 1 mmHg Transducer 0.000001 mmHg0 to 10 mmHg Transducer: 0.00001 mmHg0 to 1000 mmHg Transducer: 0.001 mmHg |

|

| Typical Relative Pressures | N2 / Liquid N2 : 10-7 Ar / Liquid Ar: 10-7 CO2 at 25 o C: 10-9 | |

| Charges (Rupees per hour) | Department ( per hour) | 3000 |

| Academic ( per hour) | 5000 | |

| Industry ( per 3 hours) | 8000 + GST | |

| Contact person | Mr. R.J. Deshpande (rjd@iisc.ac.in) | |

Alloy Preparation Laboratory

In-charge: Professor S. Suwas, Professor A. Paul, Dr. P. Padaikathan

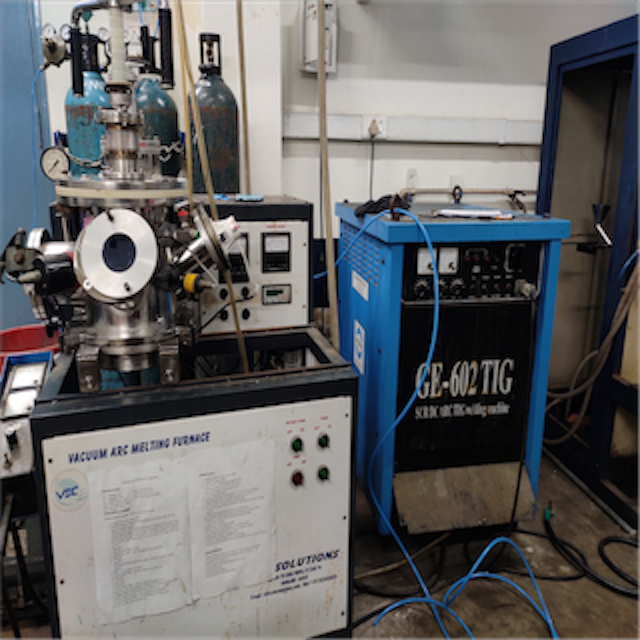

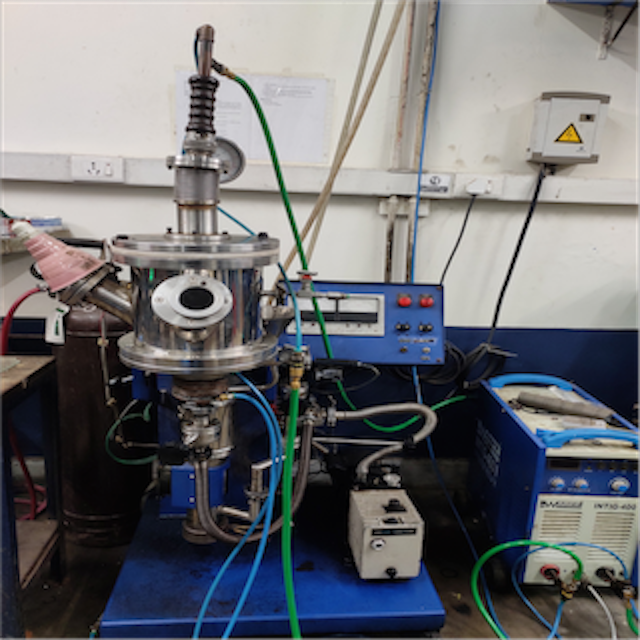

| Vacuum Arc Melting/Casting | ||

|---|---|---|

|

||

|

||

|

||

|

||

| Model | Custom Made | |

| Vacuum | 10-6 | |

| Electrode | Non-Consumable W | |

| Capacity | 3 grams to 200 grams | |

| Casting dimensions | 3 mm to 12 mm diameter/thickness | |

| Charges (Rupees per hour + GST) | Department ( per hour) | 250 (<20 grams) 300 (>20grams) |

| Academic ( per hour) | 500 (<20 grams) 700 (>20grams) | |

| Industry ( per 3 hours) | 1000 (<20 grams) 1500 (>20grams) | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

| Vacuum Quartz Sealing Unit | ||

|---|---|---|

|

||

| Model | Custom Made | |

| Vacuum | 10-6 mbar | |

| Charges (Rupees per hour + GST) | Department ( per hour) | 250 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 1000 | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

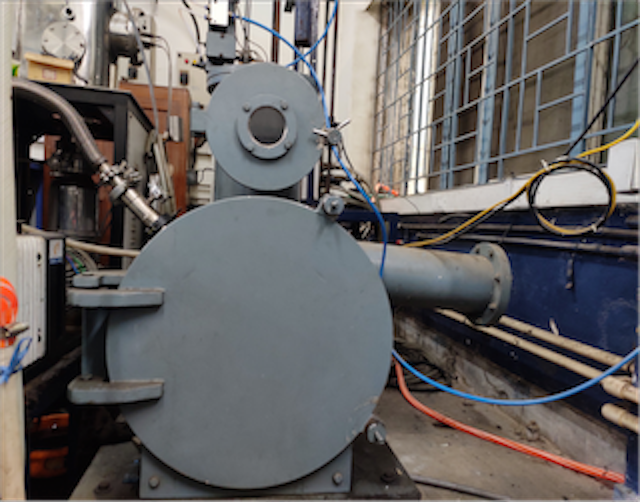

| Melt Spinning Unit | ||

|---|---|---|

|

||

| Model | Custom Made | |

| Vacuum | 10-6 mbar | |

| Charges (Rupees per hour + GST) | Department ( per hour) | 250 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 1000 | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

| Induction Melting Unit | ||

|---|---|---|

|

||

| Model | Custom Made | |

| Vacuum | 10-6 mbar | |

| Charges (Rupees per hour + GST) | Department ( per hour) | 250 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 1000 | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

| Planetary Ball Mill | ||

|---|---|---|

|

||

| Model | FRISCH Pulverisette 7 | |

| Vacuum | 10-6 mbar | |

| Working principle | Impact force | |

| Max feed Size | 5 mm | |

| Maximum sample quantity | 40 ml | |

| Final fitness | < 0.5 µm | |

| Grinding process | Dry/Wet | |

| Speed of Main disc | 100 rpm – 800 rpm | |

| Transmission Ratio | I (relative) = 1:2 | |

| Charges (Rupees per hour + GST) | Department ( per hour) | 250 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 1000 | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

Heat Treatment

In-charge: Dr. S. K. Makineni, Professor S. Suwas, Professor A. Paul

Hot air ovens

200 deg. C – 3 racks

250 deg. C – 3 racks

Tube furnaces

Two small tube furnaces- 80 mm dia – 1050 deg. C

One tube furnace – 50 mm dia-1300 deg C

One tube furnace – 100 mm dia 1700 deg. C

Box furnaces

One box furnace – chamber size 6″x1.5′- 1100 deg. C

One box furnace- chamber size 6″x1″- 1350 deg C

One box furnace – chamber size 6″x6″ – 1700 deg. C

Note:

For temperature precision to better than 5 deg. C, you need to take additional steps for calibration. If you want to heat below 300 deg.C, you can find first the difference between the actual and set temperatures by using a thermometer, which can go up to 250 deg. C. These thermometers are available in stores or local companies. Relatively high temperature furnaces should be calibrated with the help of melting point of gold (ask any PhD students in Prof. Aloke Paul’s lab for help). Note that this procedure is relatively more reliable than other methods.

For reliable results, perform your own calibration, especially after changing the tube or thermocouple. For one set of experiments use the same furnace to minimise errors. It is very difficult to calibrate 1700 deg. C furnace running in air. However, we have seen that above 1500 deg. C, furnaces are reliable even without any additional calibration.

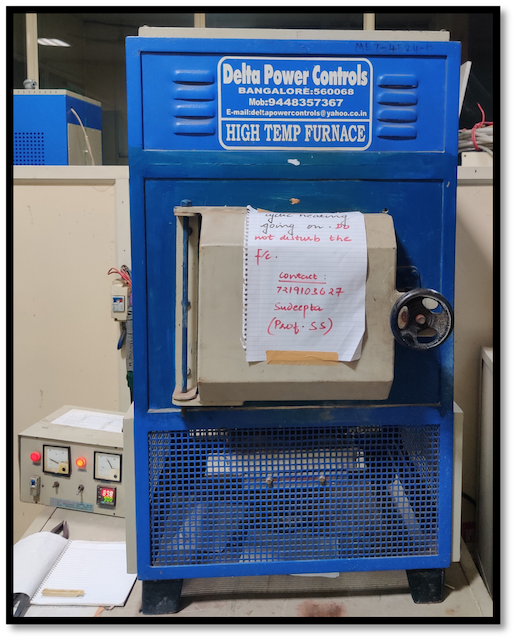

| Furnaces | ||

|---|---|---|

|

||

| Muffle Furnace (Delta Make), Max Temp: 1350oC | ||

|

||

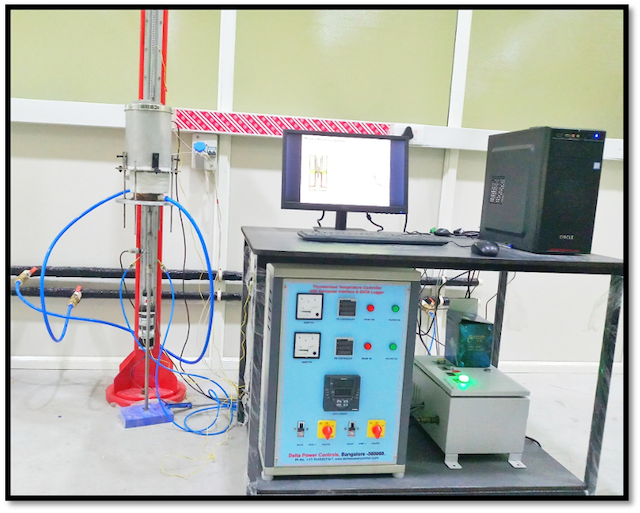

| Three Zone Tubular Furnace (Delta Make), Max Temp: 1200oC | ||

|

||

| Tubular Furnace (Delta Make), Max Temp: 1100oC | ||

|

||

| Oven (Delta Make), Max Temp: 200oC | ||

|

||

| Tublar furnace (Delta Make), Max Temp: 1400oC | ||

|

||

| Tublar furnace (Delta Make), Max Temp: 1400oC | ||

|

||

| Tublar furnace (Delta Make), Max Temp: 1400oC | ||

| Model | Delta Make | |

| Charges (Rupees per hour + GST) | Department ( per hour) | 250(<600°C); 500(>1200 in air); 750(>1200 in vacuum) |

| Academic ( per hour) | 500(<600°C); 750(>1200 in air); 1000(>1200 in vacuum) | |

| Industry ( per 3 hours) | 750(<600°C); 1250(>1200 in air); 1500(>1200 in vacuum) | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

Directional Solidification

| Modified Bridgman Furnaces for DS/Single-crystal studies | ||

|---|---|---|

|

||

| MoSi2 heating element: Max temperature: 1700 deg. C; Velocities: up to 1-200 µm/sec; Vacuum/Argon atmospheres |

||

|

||

| Graphite furnace, temperatures up to 1800 deg. C, Vacuum/Argon atmospheres; speeds 1-200 µm/sec |

||

|

||

| Low temperature furnace up to 1000 deg. C, Gradients up to 30 K/mm, and speeds up to 0.5-200 µm/sec |

||

| Charges* (Rupees per hour + GST) | Department ( per hour) | - |

| Academic ( per hour) | - | |

| Industry ( per 3 hours) | 200 (low temperature frunace); 1000 (MoSi2 and Graphite furnaces) | |

| Contact person | Prof. Abhik Choudhury (abhiknc@iisc.ac.in) | |

*material preparation and cost is the responsibility of user.

Computational Facilities

Computational facility with precision air conditioning with a redundant cooling capacity of 5 tones with variable scroll control for heat load variability.

| Clusters | ||

|---|---|---|

|

||

| The department has several computing clusters available, with contributions from the groups of Prof. T. A. Abinandanan, Prof. S. Karthikeyan, Prof. Abhik Choudhury, and Prof. Sai Gautam Gopalakrishnan. All computing clusters are located in a facility in the E-wing of the department. Interested people can contact respective faculty for usage which is FREE and therefore not guaranteed. Individual clusters are handled by respective faculties; the precision cooling is under the supervision of Prof. Abhik Choudhury |

||

Mechanical Testing

In-charge: Professor Praveen Kumar, Professor Satyam Suwas, Dr. G. S. Avadhani

Click this link for online booking.

Tensile, Compression and Bending testing

| Instron 5967 | ||

|---|---|---|

|

||

| Model | Instron 5967 | |

| Kind of Tests | Tension, Compression, Bending | |

| Strain rate (s-1) | 0.00001 to 0.1 | |

| Load Cell | 2 kN, 5 kN, and 30 kN | |

| Temperature | Room Temperature (RT) and High Temperature (HT; upto 650 °C) | |

| Charges | Department ( per hour) | RT-100; HT-125 |

| Academic ( per hour) | RT-200; HT-250 | |

| Industry ( per 3 hours) | RT-2500; HT-3000 | |

| Contact person | Mr. Kantharaja (kantharaja@iisc.ac.in) | |

| ZWICK/ROELL Z100 | ||

|---|---|---|

|

||

| Model | Zwick-Roell | |

| Kind of Tests | Tension, Compression, Bending | |

| Strain rate (s-1) | 0.00001 to 0.1 | |

| Load Cell | 0.5 kN, 10 kN and 100 kN | |

| Temperature | Room Temperature (RT) and High Temperature (HT; upto 1000 °C) | |

| Charges | Department ( per hour) | RT-100; HT-125 |

| Academic ( per hour) | RT-200; HT-250 | |

| Industry ( per 3 hours) | RT-2500; HT-3000 | |

| Contact person | Mr. Kantharaja (kantharaja@iisc.ac.in) | |

| DARTEC | ||

|---|---|---|

|

||

| Model | DARTEC | |

| Kind of Tests | Tension, Compression | |

| Strain rate (s-1) | 0.0003 to 10 | |

| Load Cell | 100 kN | |

| Temperature | Room Temperature (RT) and High Temperature (HT; upto 1200 °C) | |

| Charges | Department ( per hour) | RT-150; HT-175 |

| Academic ( per hour) | RT-300; HT-350 | |

| Industry ( per 3 hours) | RT-3000; HT-3500 | |

| Contact person | Mr. Kantharaja (kantharaja@iisc.ac.in) | |

Fatigue and dynamic testing

| INSTRON 8502 | ||

|---|---|---|

|

||

| Model | INSTRON 8502 | |

| Kind of Tests | Fatigue, 3-point Bending | |

| Strain rate (s-1) | 0.0001 to 0.1 | |

| Load Cell | 100 kN | |

| Temperature | Room Temperature (RT) | |

| Charges | Department ( per hour) | RT-100; HT-150 |

| Academic ( per hour) | RT-200; HT-300 | |

| Industry ( per 3 hours) | RT-2500; HT-3500 | |

| Contact person | Mr. Kantharaja (kantharaja@iisc.ac.in) | |

INSTRON 8032

| INSTRON 8032 | ||

|---|---|---|

|

||

| Model | INSTRON 8032 | |

| Kind of Tests | Fatigue, 3-point Bending | |

| Strain rate (s-1) | 0.0001 to 0.1 | |

| Load Cell | 100 kN | |

| Temperature | Room Temperature (RT) | |

| Charges | Department ( per hour) | RT-100; HT-150 |

| Academic ( per hour) | RT-200; HT-300 | |

| Industry ( per 3 hours) | RT-2500; HT-3500 | |

| Contact person | Mr. Kantharaja (kantharaja@iisc.ac.in) | |

| Rotating Bending Fatigue (RBF) Setup | ||

|---|---|---|

|

||

| Model | Spranktronics, Bangalore | |

| Kind of Tests | Rotating Bending Fatigue | |

| Speed | 3000 RPM | |

| Capacity | 6 Nm | |

| Temperature | Room Temperature (RT) | |

| Charges | Department ( per hour) | 100 |

| Academic ( per hour) | 200 | |

| Industry ( per 3 hours) | 2500 | |

| Contact person | Mr. Kantharaja (kantharaja@iisc.ac.in) | |

| Dynamic Mechanical Analyser | ||

|---|---|---|

|

||

| Model | GABO Qualimeter (Germany) | |

| Kind of Tests | Tension, Compression, 3-Point Bending | |

| Load Cell | 0.5 kN | |

| Temperature | -170 °C to 350 °C | |

| Charges | Department ( per hour) | RT-200; HT-300 |

| Academic ( per hour) | RT-400; HT-800 | |

| Industry ( per 3 hours) | RT-2500; HT-3000 | |

| Contact person | Mr. Kantharaja (kantharaja@iisc.ac.in) | |

Indentation

| Zwick/Roell Indenter | ||

|---|---|---|

|

||

| Model | Zwick/Roell Indenter - ZHU 250CL | |

| Kind of Tests | Rockwell/Brinell/Vickers | |

| Load Cell | 0.5 - 250 kg | |

| Charges | Department ( per hour) | 200 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 1000 | |

| Contact person | Dr. P. Padaikathan (padai@iisc.ac.in) | |

| CSM Instrumented Micro-indentation | ||

|---|---|---|

|

||

| Model | CSM Instruments | |

| Kind of Tests | Micro Hardness, High Temperature stage (up to 450°C) | |

| Maximum Load | 30 N | |

| Load resolution | 100 micro N | |

| Depth resolution | 0.3 nm | |

| Indenters | Room temperature (RT): Diamond (Vickers, Spherical, Knoop) High Temperature (HT; 450°C): Zircon (Vickers, Spherical) |

|

| Charges | Department ( per hour) | RT-; HT- |

| Academic ( per hour) | RT-; HT- | |

| Industry ( per 3 hours) | RT-; HT- | |

| Contact person | Prof. Praveen Kumar (praveenk@iisc.ac.in) | |

Depth Sensing Indentation

| Hysitron Tribo Indenter | ||

|---|---|---|

|

||

| Model | TI 900-Tribo Indenter | |

| Kind of Tests | Quasistatic Nano Indentation, Nano Scratch, SPM In-situ Imaging, Nano DMA | |

| Load capacity | (Low) 5 μN to 10 mN, (High) 10mN to 1N | |

| Temperature | Room temperature (RT) | |

| Load resolution | 1 nN | |

| Depth resolution | 0.04 nm | |

| Charges | Department ( per hour) | 200- |

| Academic ( per hour) | 500- | |

| Industry ( per 3 hours) | 2000- | |

| Contact person | Prof. Suchandrima Das (suchandrima@iisc.ac.in) Interested users may fill and submit this form |

|

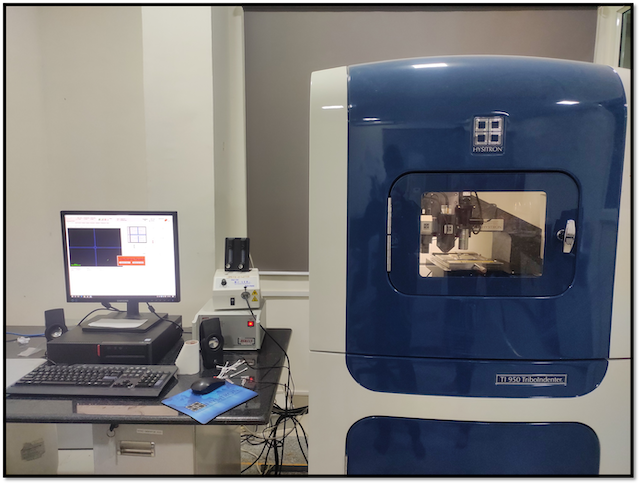

| Hysitron Nano Indenter | ||

|---|---|---|

|

||

| Model | Hysitron TI 950 Nano indenter | |

| Kind of Tests | Indentation, scratch and wear testing, In-situ SPM imaging | |

| Load capacity | (Low) up to 10 mN (5 µm displacement), (High) up to 2N (80 µm displacement) | |

| Temperature | Room Temperature (RT) and High Temperature (HT; up to 400°C) | |

| Load resolution | 1 nN | |

| Depth resolution | 0.04 nm | |

| Charges | Department ( per hour) | RT-; HT- |

| Academic ( per hour) | RT-; HT- | |

| Industry ( per 3 hours) | RT-; HT- | |

| Contact person | Prof. Praveen Kumar (praveenk@iisc.ac.in) | |

Material Processing

| Hot Extrusion Press | ||

|---|---|---|

|

||

| Model | VB Ceramic Consultants, Chennai | |

| Capacity | 100 ton | |

| Temperature | 350°C to 400°C | |

| Charges | Department ( per hour) | 300 |

| Academic ( per hour) | 600 | |

| Industry ( per 3 hours) | 3500 | |

| Contact person | Dr. G.S. Avadhani (gsa@@iisc.ac.in) | |

| Electrical Discharge Machine | ||

|---|---|---|

|

||

| Model | AU-500iA, Accutex Make | |

| Specifications | ||

| Sample details | ||

| Charges (Rupees per hour + GST) | Department ( per hour) | 300 |

| Academic ( per hour) | 500 | |

| Industry ( per 3 hours) | 1000 | |

| Contact person | Prof. Praveen Kumar (praveenk@iisc.ac.in) | |