Quick Links

PSPM

Processing, Structure and Properties of Materials

Laboratory C207, C-Wing, Department of Materials Engineering, Indian Institute of Science (IISc) Bangalore - 560012, INDIA.

Tel: +91-80-22932558 | Mail: dbanerjee_at_materials.iisc.ernet.in

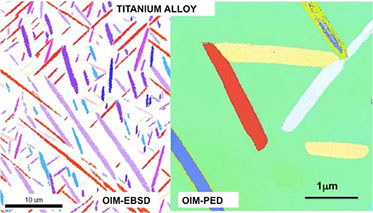

Precession Electron Diffraction (PED) assisted Orientation Imaging Microscopy (OIM) in a transmission electron microscope (TEM) is an advanced technique for an in-depth characterization with respect to orientation imaging and phase mapping at nano-scales and is capable of providing full orientation maps with nanometer resolution unlike a conventional electron backscattered diffraction (EBSD). Electron beam is scanned in combination with precession using a precession unit ( without STEM mode) in a TEM. Local diffraction patterns are acquired and cross correlated with pre- calculated electron diffraction patterns. This information can be used to generate orientation maps and virtual bright/dark field images.

Differential Scanning Calorimetry (DSC) is the most-widely used Thermal Analysis method. Thermal analyzer in our lab, NETZSCH STA 449 F3 Jupiter® allows the measurement of mass (TG) and thermal effects (DSC) simultaneously between -150°C and 2400°C, from a heating rate varying from 0.001 K/min to 50 K/min. DSC measures the difference in heat flow between sample and the reference, thus detecting various thermal events occurring in the sample. It is also capable of measuring heat capacity of the sample. Our research generally comprises of measuring the thermal events in Shape Memory Alloys and Super alloys.

MultiPrep Semi-automatic Polishing System

We employ a high-precision semi-automatic polishing system eliminating the need for manual polishing specifically for the experiments that call for a quantifiable material removal and geometric/angular control for the most demanding sample preparation for various microscopic techniques like optical, SEM-EBSD, TEM etc.

Gatan's Ultra-sonic Disc Cutter

The proven and most effective method for rapidly cutting brittle material is mechanically coupling a piezo crystal to a shaped tubular cutting tool vibrating in fine grain boron nitride slurry. The Gatan tool uses this technology to expand the standard application beyond cutting 3 mm TEM discs. It can quickly cut TEM discs from hard, brittle materials such as semiconductors, ceramics and geological samples, in thickness ranging from < 40 μm to 5 mm. The manually tuned frequency driver optimizes cutting speed for the cutting tool while minimizing mechanical and thermal induced damage.

Fishione's Twin-jet Polishing System

Twin-jet polishing is a technique for preparing the samples for preparing samples for transmission electron microscopy (TEM) and uses a chemical medium to generate electron transparent samples.

Beuhler's VibroMet 2

Vibratory polishing provides with a high quality final finishing for metallurgical samples especially for scanning electron microscopy (SEM), electron backscattered diffraction (EBSD), electron probe microanalysis (EPMA) etc.

The IsoMet Low Speed Saw is a precision sectioning saw designed for cutting all types of materials with little or no deformation. Its low kerf loss capability and great versatility in holding all types of sample shapes and configurations give the IsoMet Low Speed Saw the capability to cut virtually any material including brittle or ductile metals, composites, plastic, electronic devices etc. Using relatively low speeds (0-300 rpm) and applications specific continuous rim diamond blades, the IsoMet Low Speed Saw achieves an as cut surface which is generally free of damage and distortion.

Materials 25:

Materials 25 is a DELL Power Edge R720 rack server.

Specifications:

2 x Intel® Xeon® E5-2630 2.3GHz, 15M Cache, 7.2GT/s QPI, 6C, 12T, 95W (

Dual CPU)

64 GB 8 x 8GB RDIMM, 1600 MHz, ( 24 Memory Slots) Upto 768GB)

It consists of 1TB disk space. The server can run MPI based codes and softwares.

- Thermo-Calc 3.1: With TTNI8 Ni-alloys database and TTTI3 Ti-alloys database

- Carine 3.1

- Crystal maker 2.5

- TSL OIM Analysis 6.2

TEM-OIM

DSC

Semiautomatic Polishing

Ultrasonic Disc Cutting

Twinjet Polishing

Vibratory Polishing

Low Speed Cutting

Lab Server

Softwares