Quick Links

PSPM

Processing, Structure and Properties of Materials

Laboratory C207, C-Wing, Department of Materials Engineering, Indian Institute of Science (IISc) Bangalore - 560012, INDIA.

Tel: +91-80-22932558 | Mail: dbanerjee_at_materials.iisc.ernet.in

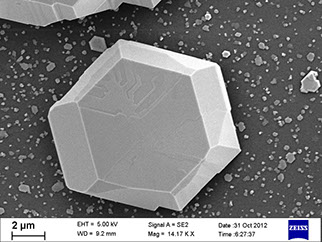

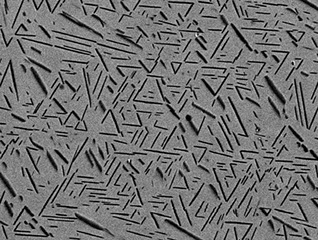

Microstructural Evolution in Gallium Nitride Films

GaN and related III-V nitrides are most promising materials for optoelectronic applications ranging from UV to visible regions. Here we are trying to generate a deeper understanding especially concerning the low temperature nucleation layers by investigating the microstructural evolution of nucleation layers for the subsequent growth of GaN epi layers.

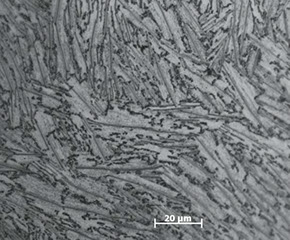

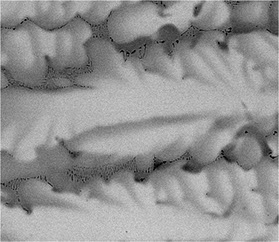

Creep in Low Temperature Regime in Titanium Alloys

IMI 834 is a high temperature alloy and is widely known for its potential applications in discs and blades in compressors of jet engines that experience temperatures from ambient to 600 degrees celcius. Here we study and model creep behavior in low temperature regime and study the effect of dynamic strain ageing during creep.

Intermetallic Eutectic Alloys

Metal/Intermetallic composites have been extensively studied but so far no study has been done for intermetallic/intermetallic composites. Such composites have been discovered recently in the Ni-Al-Zr ternery system. Here we are focused at understanding the effects of microstructural scale on mechanical behavior of such composite structures.

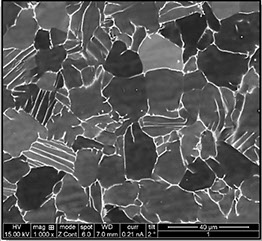

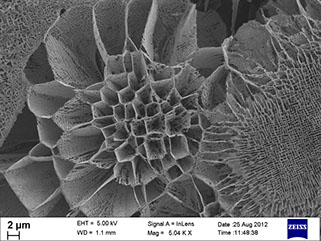

Processing, Structure, Texture and Crystal Plasticity in Two Phase Titanium Alloys

We study the effect of process variables in microstructure and microtexture evolution in commercial Titanium alloys. Different processing paths such as hot compression and friction stir processing are explored for this purpose. The alpha globularization process along with the beta recrystallization is studied using advanced SEM and TEM techniques. We are also looking at the non-deformed alpha/beta structures for variant distribution.

High Temperature Shape Memory Alloys

High temperature shape memory alloys are used for actuator applications for aerospace vehicles. In Ni-Ti-Hf shape memory alloys, we are studying the effects of Pt addition on the transformation temperature, shape memory and pseudoelastic depth recovery, phase stability, structure and substructure of martensite.

Phase stability aspects of cast Nickel based Superalloys

Ni-based superalloys find application in turbine blades of aero engines. The remarkable strength of this class of alloys is due to their microstructure containing high volume fraction of gamma prime phase and presence of various alloying elements that promote better creep properties at services temperatures. Here we study systematically study the effects of various alloying additions, on the phase stability of Ni-base superalloys.

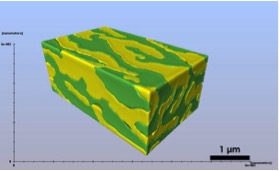

Three dimensional microstructural characterization

Three dimensional microstructural characterization becomes important for exploring several microstructural parameters like inter-connectivity of the features, their size and shapes that cannot be deduced using two dimensional imaging. We are using serial sectioning techniques and trying to establish a methodology to reconstruct and study three dimensional microstuctures in some engineering alloys to better elucidate their properties.

Highly Alloyed Materials

Traditionally Metallurgists have focused on understanding solid solution strengthening in dilute alloys. However an emerging class of alloys is based on highly concentrated systems. Fundamental approach of this project is to determine the atomic distribution in the highly concentrated alloys through experimental and modeling techniques, and then understand the solid solution strengthening mechanisms in them. Co-Ni-Pd system, which has a single solid solution phase at higher concentrations, is selected for this work.