|

GAS CARBURISING (TECH. TRANSFERRED TO INDUSTRY) |

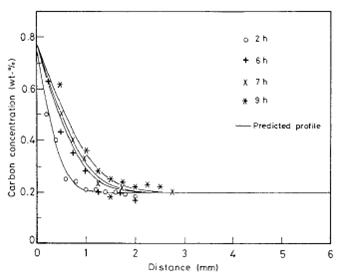

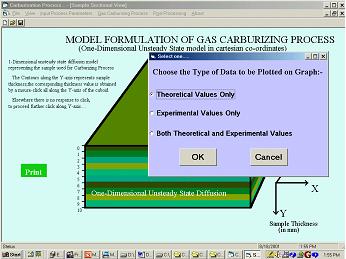

| A mathematical model has been developed for the gas carburizing (diffusion) process using Finite Volume Method. The computer simulation has been done for an industrial gas carburizing process. Modelís predictions are in very good agreement with industrial experimental data (Figure 1) and with the data collected from the literature. Study of various mass transfer and diffusion coefficients has been done in order to suggest that which correlations should be used for the gas carburizing process. The model (we call it GasCarb) has been made user friendly using Graphical User Interface so that it can be used in the industry on day-to-day basis (Figure 2). Sensitivity analysis shows that case depth increases as the carburizing time, atmospheric carbon potential of the process increases. Case depth also increases with increase in diffusion and mass transfer coefficients. This software can control the process online and gives an in-depth analysis of the process. |

Figure 1. Comparison between the plant and GasCarb model's results for case depth. |

Figure 2. GUI developed for the GasCarb software. |

| This sofware is being used by some

industries such as

TVS MOTORS. Interested industries/person can contact us. We are also looking for some marketing people to market this

software to other industries. For further details or queries or publication related to this, kindly contact us at the address given on the web-site. |