|

Mechanical properties of Thin films |

|

|

Contact deformation in TiN hard coatings |

|

|

Multilayers of TiN/AlTiN |

|

|

Benefits of multilayering in crack resistance |

|

|

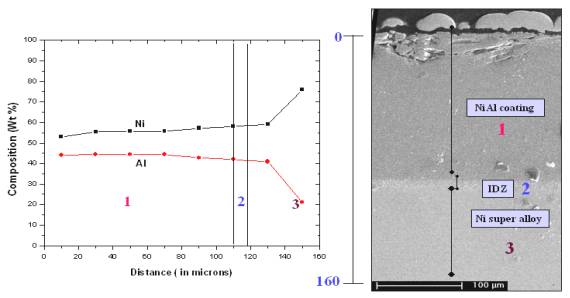

NiAl bond coats on Super Alloys |

Contact deformation in TiN hard coatings

|

|

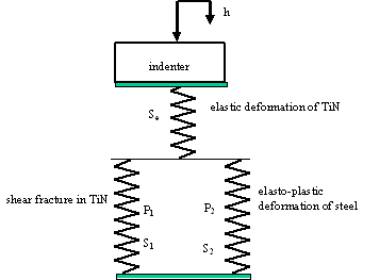

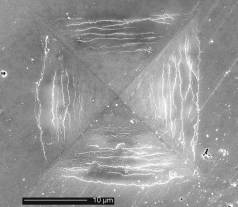

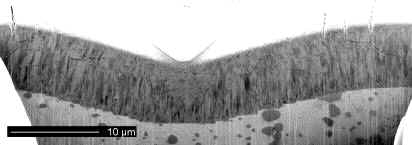

Thin columnar hard coatings of TiN accommodate indentation by slipping along their “weak” columnar boundaries. There is little or no transverse shear of the columns! |

||||

|

|

|||||

|

|||||

|

|

||||

| Load

sharing: P=Total P2=supported by expanding cavity in substrate P1=supported by TiN columns before sliding |

|||||

|

|

|||||

|

Thick films and soft substrates lead to a new mode of cracking arising out of a strain mismatch between a plastic substrate and a largely elastic film. |

|||||

|

|

|||||

|

|

|||||

|

|

Domains of cracking /columnar shear Soft substrates cannot support thick films! If a coating on soft substrate performs poorly, making it thicker may make matters worse! |

||||

|

|

|||||

Multilayers of TiN/AlTiN

|

Varying the substrate rotational speeds and a spatially varying plasma concentration in cathodic arc evaporation can lead to a wide variety of multilayer structures. |

|

|

|

Schematic of Cathodic arc evaporation with planetary rotation |

|

|

|

|

Slow rotation |

Fast rotation |

|

|

|

|

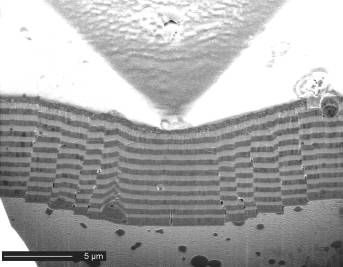

Out of focus phase contrast bright field TEM images reveal small fluctuations ~2-4 nm layers which are homogeneously distributed ( fast rotation) or which lie at the boundary between alternating ~20-50nm layers of TiN and AlTiN (slow rotation) |

|

|

|

|

How does multilayering influence indentation cracking?

| Monolithic

TiN displays edge and inclined cracking at low loads.

|

|||||||||||

|

|

||||||||||

|

Multilayering increases the critical load for edge cracking, while inclined cracks becomes discontinuous

|

|||||||||||

|

|||||||||||

|

Extent of bending of layers (as opposed to columnar sliding) increases with layer refinement and offers an additional mechanism of strain accommodation |

|||||||||||

|

|

|||||||||||

|

|||||||||||

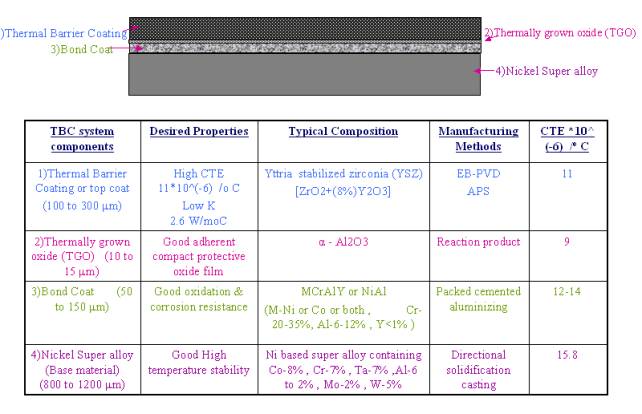

Small Scale Fracture testing of bond coated super alloy

Thermal Barrier Coating (TBC) System

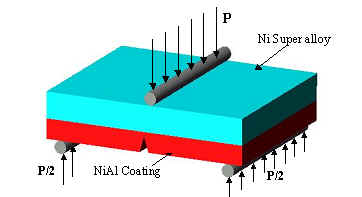

Three Point Bending for studying Fracture Properties

FIB Notched Specimen: Depth of the Notch = 15 microns