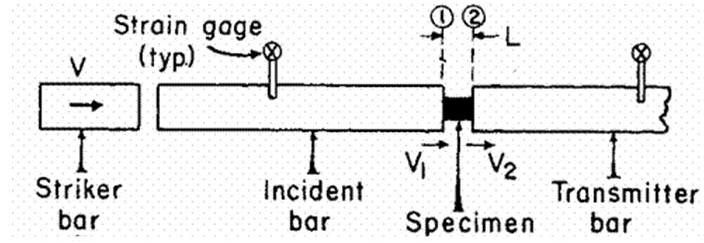

The Split-Hopkinson Pressure Bar allows for

dynamic deformation at high strain rates (103-104 /s). The SHPB

in our lab is a compression testing rig, though

plans are being made for a tensile testing apparatus. The schematic of the basic Hopkinson bar setup shows two long

cylindrical

bars of the same diameter, called the incident and transmitted bars. In a

compression test, the sample sits sandwiched between the incident and

transmitted bars. A striker bar of the same

diameter is propelled using a gas gun so that it strikes the incident bar

squarely on the end. This generates a compression wave which travels down the

incident bar. Part of the wave is reflected and part is transmitted through the

interface with the specimen. The stress pulse continues through the specimen and

into the transmitted bar. The incident stress pulse and transmitted stress pulse

are measured in real-time using strain gages on the incident and transmitted

bars. If the two bars remain elastic and wave

dispersion ignored, then the measured stress pulses can be assumed to be the

same ones acting on the sample. One could procure the stress strain curves from

this. The high frequency transducers and the digital storage oscilloscope help

in acquire and storing data at high rates. We will use the technique to

deform materials at high strain rates and at different temperatures and up to

different strains. The deformed samples are then characterized will be

characterized using the TEM to facilitate the understanding of deformation

mechanisms.

cylindrical

bars of the same diameter, called the incident and transmitted bars. In a

compression test, the sample sits sandwiched between the incident and

transmitted bars. A striker bar of the same

diameter is propelled using a gas gun so that it strikes the incident bar

squarely on the end. This generates a compression wave which travels down the

incident bar. Part of the wave is reflected and part is transmitted through the

interface with the specimen. The stress pulse continues through the specimen and

into the transmitted bar. The incident stress pulse and transmitted stress pulse

are measured in real-time using strain gages on the incident and transmitted

bars. If the two bars remain elastic and wave

dispersion ignored, then the measured stress pulses can be assumed to be the

same ones acting on the sample. One could procure the stress strain curves from

this. The high frequency transducers and the digital storage oscilloscope help

in acquire and storing data at high rates. We will use the technique to

deform materials at high strain rates and at different temperatures and up to

different strains. The deformed samples are then characterized will be

characterized using the TEM to facilitate the understanding of deformation

mechanisms.

The last stages of the fabrication are underway - the

maraging steel bars are being aged and machined. The gas gun is firing as

designed.

Some images of the SHPB apparatus are shown below.