|

PACK CARBURISING |

Pack

carburization is the oldest method among the case hardening treatments

and sufficient attempts has not been made to understand this process in

terms of heat and mass transfer, effect of alloying elements,

dimensions of the sample, etc. Thus, a two dimensional mathematical

model in cylindrical co-ordinate is developed for simulating pack

carburization process for chromium bearing steel (a ternary system

(Fe-C-Cr)) in this study. Heat and mass balance equations are solved

simultaneously where surface temperature of the sample varies with

time, but the carbon potential at the surface during the process

remains constant. Fully implicit finite volume technique is used to

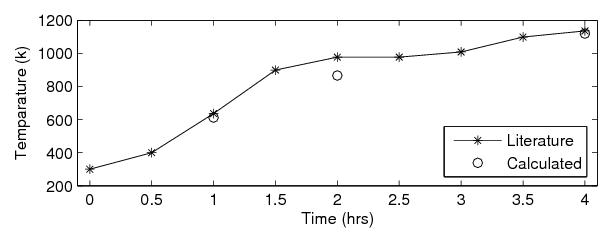

solve the governing equations. A good agreement has been found between

the predicted and published data.

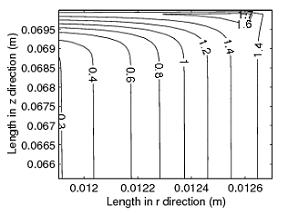

It is observed

that two dimension analysis gives better description of the process

than one dimension. It is found that the effect of second dimension on

the craburising process is significant especially in predicting the

case depth near the corners of the sample. Neglecting the second

dimension in modeling and subsequently analysis of the results on case

depth may provide wrong interpretation and thus may affect the

operating life of the specimen. Sensitivity analysis shows that as the

size of the sample increases the case depth is decreased and thin layer

of charcoal packing increases the case depth. |

Figure 1. Comparison between computed and published expt. temperature data. |

Figure 2. Computed carbon concentration profile within the specimen (high C concn. at the corner is evident). 2D pack carburizing at 1173 K for 6 hours. |

| For further details or queries or publication related to this, kindly contact us at the address given on the web-site. |