Modelling of Granulation/Pelletisation-cum-Iron Ore Sintering Process

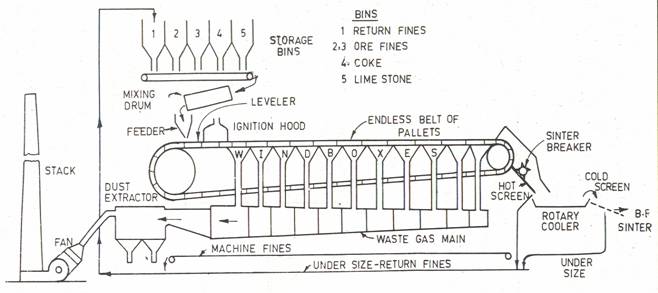

Sintering of iron ore is an integral part of iron making to improve the performance of Blast Furnaces. The process of sintering is preceded by the preparation of sinter charge mix where the base mix material (iron ore, coke breeze, flux, return sinter and water) undergoes agglomeration in a rotating drum.

The resulting granules are charged on to a moving strand where they are leveled off to form a uniform bed. The top of the bed is ignited with the help of burners to initiate combustion of coke. As the material is conveyed along the strand a heat wave progresses downwards with the combustion of coke and sintering of granules.

The air required for combustion is sucked through the surface of the bed and the products of combustion are exhausted through wind boxes situated below the strand. The operating parameters of the sinter strand are controlled in such a way that the completion of sintering (known as burn-through point) takes place just before the last wind box.

Here, the balling step is more critical. Sub-optimal balling is invariably compensated by slowing the strand speed, lowering the bed height, increasing the firing temperature, etc. Net result is lower productivity. Therefore, balling and sintering steps must be examined in tandem as two interlocking components of the same problem.

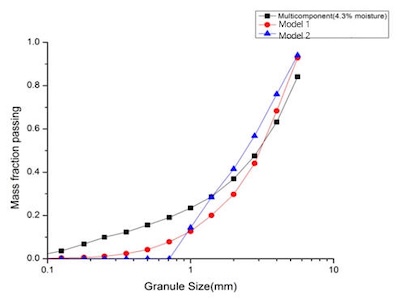

During the granulation process fines get deposited or layered itself onto coarse particles, as a result granulated product in turn is larger in size and narrower in size distribution than the original feed. Two models have been developed for granulation:

- Model 1: Based on Litster et al. approach

- Model 2: Based on Kapur et al. approach

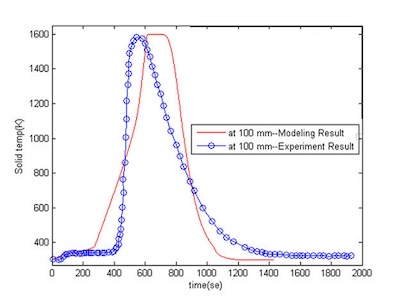

Sintering model is a complex model which considers all the major physico-chemical reactions over a large range of temperature which are taking place during the iron ore sintering such as:

- Evaporation/condensation of moisture ahead of the flame front

- Calcination of limestone near the flame front

- Coke combustion in the flame front

- Melting/solidification

This sintering model has been combined with the granulation/pelletisation model making it a full comprehensive model which is available today to take care of both granulation-cum-sintering process simultaneously.

For further details, queries, or publications related to this research, please contact us through our contact information on the website.