|

MODELING LIQUID FLOW IN PRESENCE OF GAS FLOW IN PACKED BEDS |

|

In

our group, the focus is on the study of flow of non-wetting liquid

through a porous media under the influence of gas. In many

metallurgical reactors, we have situations where the liquid phase is

non-wetting and it flows counter current or co current or even cross

current to the gas phase. A typical example of this is the lower part

of an iron making blast furnace where molten metal and slag descend

over the coke matrix, cross current and counter current to the gas

flow. Research has shown that non - wetting liquid flows as droplets

and rivulets, falling through the bed, and continuously breaking and

joining with each other. This is different from wetting flows where the

liquid phase flows as film around the packing particles. Under the

influence of gas, especially laterally injected gas, the liquid holdup

in the bed is also quite different as compared to gas liquid counter

current or co current flow conditions. Hence, our efforts have been

directed towards the direction of a fundamental understanding of the

nature of motion of these droplets and rivulets falling through the

bed. We try to model the discrete behavior of liquid flow through a force balance approach

postulated by Gupta et

al. (1996, 1997). Continuum models have failed to predict

the liquid flow path (region) when the source is a point source. |

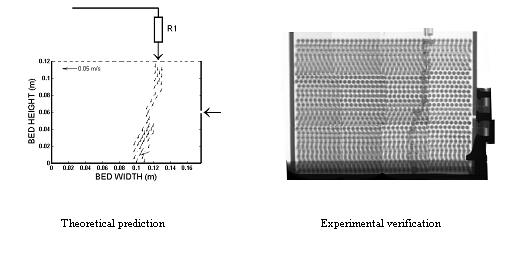

Figure 1. |

We

have postulated a new

theory to model the non-wetting flow in a packed bed considering the

liquid flow as discrete in nature. Liquid rupture theory has also been

incorporated recently in order to use this theory for wider

applications. Figure 1 shows a comparison between the proposed theory

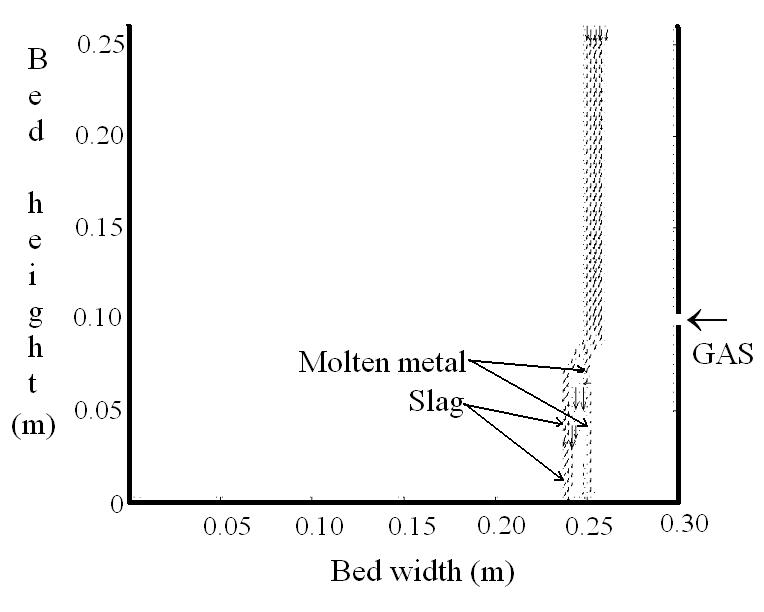

and experimental results. Figure 2 shows the possible application of

this theory in an Ironmaking blast furnace. The gas flow has been

modeled by solving Navier-Stoke equation in turbulent condition. We

employ x-ray

technique for liquid

flow visualization in a packed bed to validate our results.

|

Figure 2. Flow of slag and iron at 40 m/s increasing gas blast velocity. |

| Efforts are underway in our group to model liquid flow path in the random bed considering various liquid holdups, so as to gain a proper understanding of the gas-liquid maldistribution in the bed. Also the effect of raceway hysteresis on gas-liquid flow is being investigated. |

| For further details or queries or publication related to this, kindly contact us at the address given on the web-site. |