|

MANUFACTURE OF BORON CARBIDE |

|

Figure 1. Boron carbide process in operation. |

|

Boron

carbide is produced in a heat resistance furnace using boric oxide and

petroleum coke as the raw materials. In this process, a large current

is passed through the graphite rod located at the center of the

cylindrical furnace, which is surrounded by the coke and boron oxide

mixture. Heat is generated at the surface of the electrode, due to

which boron oxide reacts with the coke to produce boron carbide (Figure

1). The process is inefficient in terms of the production of boron

carbide as only 15% charge gets converted into boron carbide. No

published attempt has been made to optimise the process using

mathematical modelling. Also, experimentally not much work has been

done. Therefore, in this first ever study both mathematical and

physical modelling has been carried out. |

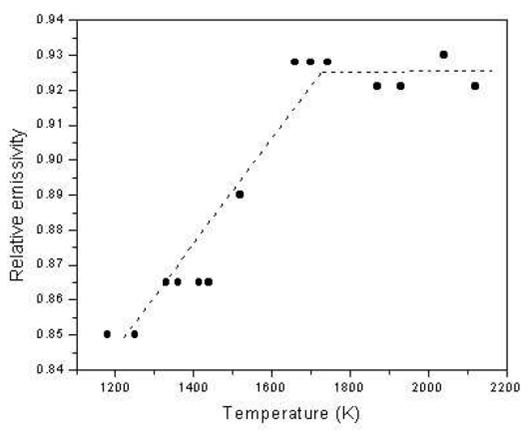

Figure 2. Plot of temperature vs. relative emissivity for graphite electrode. |

|

In

mathematical modelling, simultaneous heat and mass transfer model has

been developed for the resistance-heating furnace, considering boron

carbide formation as a typical carbothermal reduction. Coupled

transient, partial differential equations have been worked out. These

equations have been solved numerically, using the implicit finite

volume method to obtain the profiles of temperature and volume fraction

reacted (B4C formation) in the furnace. Modelís predictions are

validated against experiments and initially it is found that the match

is poor. This led us to think to find out the uncertainties associated

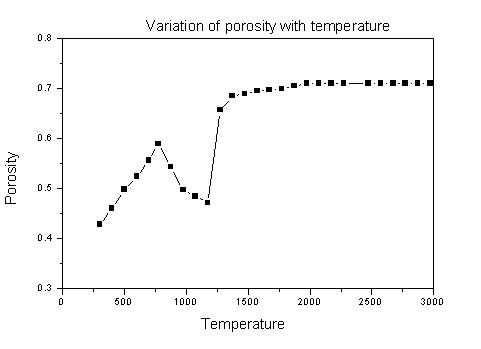

with either the experiments or modeling. It is found that porosity can

affect the simulation results significantly. Therefore, experiments

were performed to measure the porosity of the mixture/product at

various temperatures (Figure 3). Similarly significant inaccuracies are

found in temperature measurements, thermal conductivity of coke, etc.

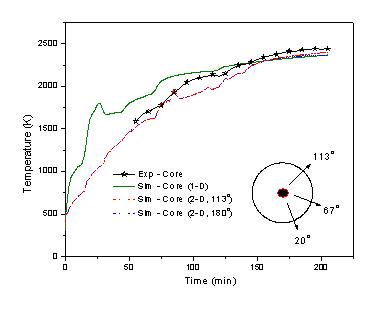

After incorporation of the above corrections a good match is found

between the computed and experimental results (Figure 4). This gives a

fine example that how a mathematical model can be used to improve the

physical model. A Graphical User Interface for the process

has also

been developed.

This process has been optimised experimentally now. A 2-D mathematical model

with GUI is also available for the process.

|

Figure 3. Plot of temperature vs. porosity Figure 4. Comparison of simulated (1D & 2D) variation for boric acid and graphite mixture. results with experimental core temp. |

|

This

technology and sofware

are ready to transfer to interested industries

(Currently under negotiation with

Indian Armour Systems Pvt. Ltd.).

Interested industries/person, even to setup a plant or transfer of

technology can contact us.

For further details or queries or publication related to this, kindly contact us at the address given on the web-site. |